Precision Engineering with Boron Nitride (BN) Nozzles: Applications, Properties, and Innovations

Introduction: Unveiling the Power of Boron Nitride (BN) Nozzles

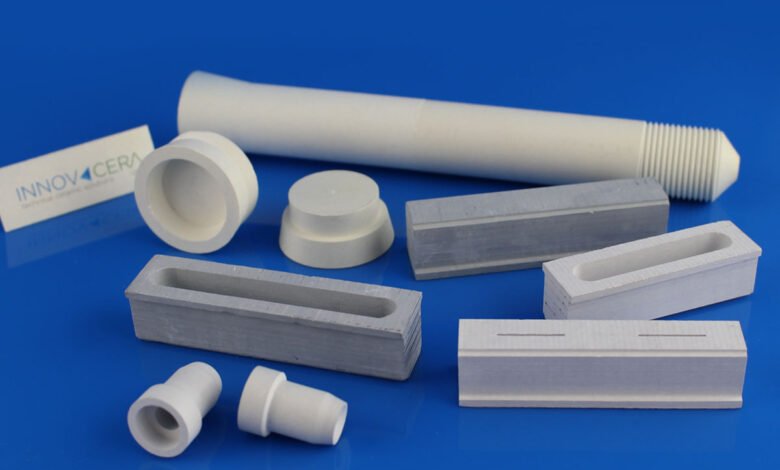

Boron Nitride (BN) nozzles stand as a pinnacle of precision engineering, offering exceptional properties and versatility in various industrial applications. This article delves into the significance, properties, manufacturing processes, applications, benefits, and advancements associated with BN nozzles, showcasing their pivotal role in driving efficiency, reliability, and innovation across industries.

Understanding Boron Nitride (BN) Nozzles: The Epitome of Precision

BN nozzles are advanced ceramic components crafted from boron and nitrogen atoms, featuring a hexagonal lattice structure. They exhibit remarkable properties such as high thermal stability, excellent thermal conductivity, chemical inertness, and resistance to wear, making them ideal for applications requiring precise and efficient fluid or gas flow control.

Properties of Boron Nitride (BN) Nozzles: Unraveling Superiority

- High Thermal Stability: BN nozzles can withstand extreme temperatures without structural degradation, making them suitable for use in high-temperature environments such as metalworking, welding, and thermal processing.

- Excellent Thermal Conductivity: They possess high thermal conductivity, ensuring efficient heat transfer and dissipation, crucial for applications involving heat exchangers, cooling systems, and thermal spray processes.

- Chemical Inertness: BN nozzles are chemically inert and resistant to corrosion from acids, alkalis, and harsh chemicals, making them durable and reliable in aggressive industrial environments.

- Wear Resistance: They exhibit exceptional wear resistance, minimizing abrasion, erosion, and material loss, leading to prolonged service life and reduced maintenance costs.

- Precision Machining: BN nozzles can be precision-machined to achieve intricate geometries, tight tolerances, and customized designs, allowing for precise fluid or gas flow control and distribution.

Manufacturing Processes for Boron Nitride (BN) Nozzles: Craftsmanship at its Finest

- Hot Isostatic Pressing (HIP): HIP is a common method for producing dense and uniform BN nozzles, where boron nitride powder is compacted under high temperatures and pressures to achieve the desired properties.

2. Extrusion and Machining: Extrusion processes followed by Boron Nitride (BN) Nozzle precision machining are employed to fabricate BN nozzles with specific dimensions, geometries, and surface finishes tailored to application requirements.

- CVD Coating: Chemical Vapor Deposition (CVD) techniques can be used to deposit BN coatings onto nozzle substrates, enhancing their surface properties, wear resistance, and thermal performance.

- Additive Manufacturing: Advanced additive manufacturing technologies, such as 3D printing, enable the production of complex BN nozzle designs with intricate internal channels and structures, offering new possibilities in fluid dynamics and flow control.

Applications of Boron Nitride (BN) Nozzles: Powering Precision Across Industries

- Metalworking and Welding: BN nozzles are used in metalworking processes, such as cutting, drilling, and welding, for precise coolant delivery, heat dissipation, and protection against molten metal splatter.

- Thermal Spray and Coating: They find applications in thermal spray processes for coating deposition, where they facilitate uniform coating distribution, controlled particle acceleration, and efficient heat transfer.

- Chemical Processing: BN nozzles are employed in chemical processing industries for fluid handling, mixing, and dispersion, offering corrosion resistance, chemical inertness, and reliability in handling corrosive fluids and gases.

- Aerospace and Defense: They are utilized in aerospace and defense applications for propulsion systems, rocket engine cooling, and fuel atomization, where precise fluid dynamics and thermal management are critical.

- Semiconductor Manufacturing: BN nozzles find applications in semiconductor manufacturing for gas delivery, chemical vapor deposition (CVD), and wafer cleaning processes, ensuring contamination-free operation and precise gas flow control.

Benefits of Boron Nitride (BN) Nozzles: Precision, Reliability, and Efficiency

- Precision Control: BN nozzles offer precise control over fluid or gas flow rates, direction, and distribution, ensuring uniform coverage, efficient cooling, and optimized process parameters.

- Reliability: They are highly reliable and durable, withstanding harsh operating conditions, thermal cycling, and chemical exposure without degradation or performance loss.

- Efficiency: BN nozzles contribute to process efficiency by enhancing heat transfer, minimizing waste, reducing downtime, and optimizing resource utilization in industrial operations.

- Cost-Effectiveness: Their long service life, minimal maintenance requirements, and resistance to wear and corrosion translate into cost savings and improved operational efficiency over time.

Innovations and Future Trends in BN Nozzle Technology: Pioneering Progress

- Advanced Coatings: Research focuses on developing advanced coatings for BN nozzles, such as self-healing coatings, anti-fouling coatings, and nanostructured coatings, to enhance performance, durability, and functionality.

- Smart Nozzle Designs: Innovations in nozzle design include smart features such as integrated sensors, actuators, and flow control mechanisms, enabling real-time monitoring, feedback control, and adaptive operation in response to changing conditions.

- Materials Integration: BN nozzles are being integrated into composite materials and hybrid structures, combining the benefits of BN with other materials such as metals, polymers, and ceramics for enhanced performance and multifunctionality.

- Additive Manufacturing Advancements: Additive manufacturing techniques continue to evolve, enabling the fabrication of BN nozzles with complex geometries, internal channels, and customized features, opening new avenues in fluid dynamics and process optimization.

Conclusion: The Future of Precision Engineering with BN Nozzles

In conclusion, BN nozzles represent a pinnacle of precision engineering, offering a unique combination of properties, versatility, and reliability across a wide range of industrial applications. As research, development, and innovation continue to drive progress in materials science and manufacturing technologies, the potential of BN nozzles in powering precision, efficiency, and sustainability in various industries is boundless.